Model 190 and 200 Series

GOVRO Standard Automatic Vertical Indexing Machines Models 190 and 200 will perform multiple operations on three sides of a part simultaneously. Machines will handle up to 19 machining units with automatic 8-station index and clamp/unclamp of parts. Units may be mounted horizontally, vertically or at an angle. Set-up time should average two to three hours within a family of similar parts.

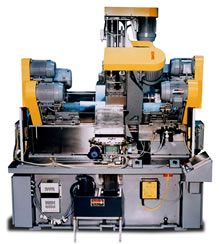

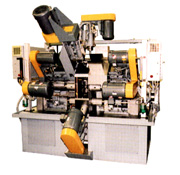

Model 190

Model 190, with rotary magazine automatic loading device.

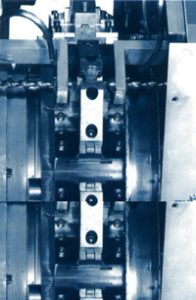

Govro Automatic Universal Chucks

Self-equalizing chucks with two master jaws and replaceable top jaws. Newly improved design is more rigid, increasing accuracy and finished part quality. Air operated with up to 7,000 lbs clamping power per chuck at 100 PSI. Automatic clamp, unclamp and eject of parts. Dual workpiece chucking is available – doubling machine production.

Model 2000

Govro Model 2000 standard automatic vertical indexing machines have excellent flexibility for producing a variety of parts and will perform multiple operations on three sides of a part simultaneously. Up to 18 Govro machining units may be accommodated, depending on the operations required. Units may be mounted at any angle. The face gear coupling design gives the automatic 8-station index greater rigidity and location accuracy, thereby increasing finished part precision and reproducibility. Setup/changeover time is minimal within a family of similar parts.

Model 2000

This 8-station vertical indexing machine, performs multiple operations on 3-sides of a part. Face gear coupling in the index improves accuracy and rigidity. 1/8 -1/2″ brass pipe fittings are machined from saw cut blank stock to finished parts in under 5 seconds.

|

MODEL 2000 SPECIFICATIONS

Designed for 300, 33, or 46 Series Units |

|

| GOVRO Index Table Diameter # of Stations Index Accuracy Index Time Index Motor GOVRO Units Horizontal Vertical Vertical Columns Coolant Capacity Chip Conveyor Floor Space Height Shipping Weight |

Geneva type, face gear coupling 28″ 8 +/- 3 arc seconds 1 to 3 seconds 1 HP Up to 18 Up to 12 (6 on right, 6 on left) Up to 6 Fabricated Steel 50 gal. Included 100″ x 140′ 98″ Approx. 17,000 lbs. |