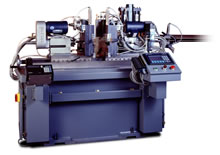

Model 165 Machine

The Model 165 is designed for drilling/tapping multiple radial holes simultaneously, plus an optional vertical or angular operation. With Govro flexibility, families of similar parts may be processed on one machine. The machine base is a cast iron top plate, with coolant trough, circular T-slots and center dowel for fixture location, on a fabricated base.

Any GOVRO unit, except Series 46, may be specified. Range of operations are the same as shown for the individual units used.

Electrical controls include programmable logic controls with operator interface terminal. Machine may be preprogrammed for a family of parts, as well as emergency stops for machine malfunction, flags for routine maintenance, broken tool detection and tool load monitors. Standard controls for single cycle operation include two start cycle switches wired for anti-tie down (continuous operation permitted with automatic load/unload devices). Special wiring can be supplied with electrically interlocked circuit for sequence operation, indexer or transfer device.

Model 165

This GOVRO Model 165 machine, drills 16 radial holes in high carbon steel rings, eight simultaneously.

Model 175 Machine

The Model 175 is designed for drilling or tapping opposing holes with single spindle and/or multiple spindle heads. An additional vertical or angular unit may be added as needed. Automatic load/unload is available as well as bar-feed and cut-off for both tube and bar stock. The machine is constructed with fabricated steel, normalized, with ground top surface and coolant trough, keyway or dowels for fixture and unit location. Solid construction enhances long-term durability. Custom machine base sizes are available.

Any GOVRO unit may be specified, range of operations are covered in unit specifications.

Electrical controls include programmable logic controls with operator interface terminal. The machine may be preprogrammed for machining a family of similar parts, as well as emergency stops for machine malfunction, flags for routine maintenance, broken tool detectors, and tool load monitors. Standard controls for single cycle operation include two start cycle switches wired for anti-tie down (continuous operation permitted with automatic load/unload devices).

The Govro-Nelson Co. has a long history of solving tough manufacturing problems with innovative machine designs. GOVRO has been successful in combining high volume production with low cost operation and exceptional quality.

Send GOVRO engineers your part specifications for a machine design to improve yow manufacturing.

Model 175

Designed for drilling or tapping opposed holes. This machine cut-off and chamfered tubing ranging in length from 1-1/2” to 12” with changeover between part lengths of less than a minute.